Plasma Table: A Modern Tool for Precision Cutting

The plasma table, also known as a CNC plasma table or plasma CNC table, has become an integral tool in industries ranging from automotive to construction and artwork. This advanced piece of machinery is used for precise cutting of materials, making it an invaluable asset for professionals and hobbyists alike.

What Is a Plasma Table?

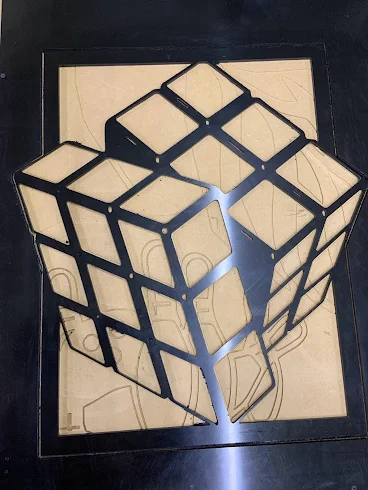

A plasma table is a specialized type of CNC (Computer Numerical Control) machine designed to cut through electrically conductive materials like steel, aluminum, brass, and copper. It achieves this feat by using a high-speed jet of ionized gas, or plasma, which is generated by forcing compressed air at high speeds through a small nozzle while introducing an electrical arc.

How Does a CNC Plasma Table Work?

In a CNC plasma table, the cutting process is controlled by a computer. The operator inputs a CAD (Computer-Aided Design) file into the CNC controller, which then directs the machine where to cut. This technology allows for highly precise cuts, making it ideal for intricate designs and complex shapes.

Choosing the Right Plasma CNC Table

When choosing a plasma CNC table, size is one of the most important considerations. Plasma tables are available in different sizes, including 6x12, 5x10, 4x8, 5x5, 4x4, and 4x2. The size you choose will depend on your specific needs and the space available in your workshop. Other factors to consider include the power of the plasma cutter, the quality of the components, and the software included with the machine.

For more information about plasma tables and how they can benefit your business or hobby, visit premierplasmacnc.com.

Why Trust Premier Plasma CNC?

Premier Plasma CNC is a reputable manufacturer of plasma CNC tables, known for delivering some of the best CNC plasma cutting machines in the USA. When you choose Premier Plasma CNC, you're investing in quality, precision, and reliability.

Conclusion

Whether you're a professional fabricator or a hobbyist, a plasma table can be a game-changer. It provides the precision and control needed to create intricate designs and shapes, making it an invaluable asset in diverse industries. To learn more about these advanced machines, visit premierplasmacnc.com.